About stainless steel...

Properties of Stainless Steel

Unlike mild steel, which rusts readily when exposed to air and moisture, the chromium in stainless steel forms a corrosion-resistant and invisible chromium oxide film. This film is resistant to water and air and therefore prevents corrosion both on and beneath the surface. It is also lustrous and tough, and if the film is scratched or damaged it reforms quickly in oxygen, thus repairing itself (called passivation).

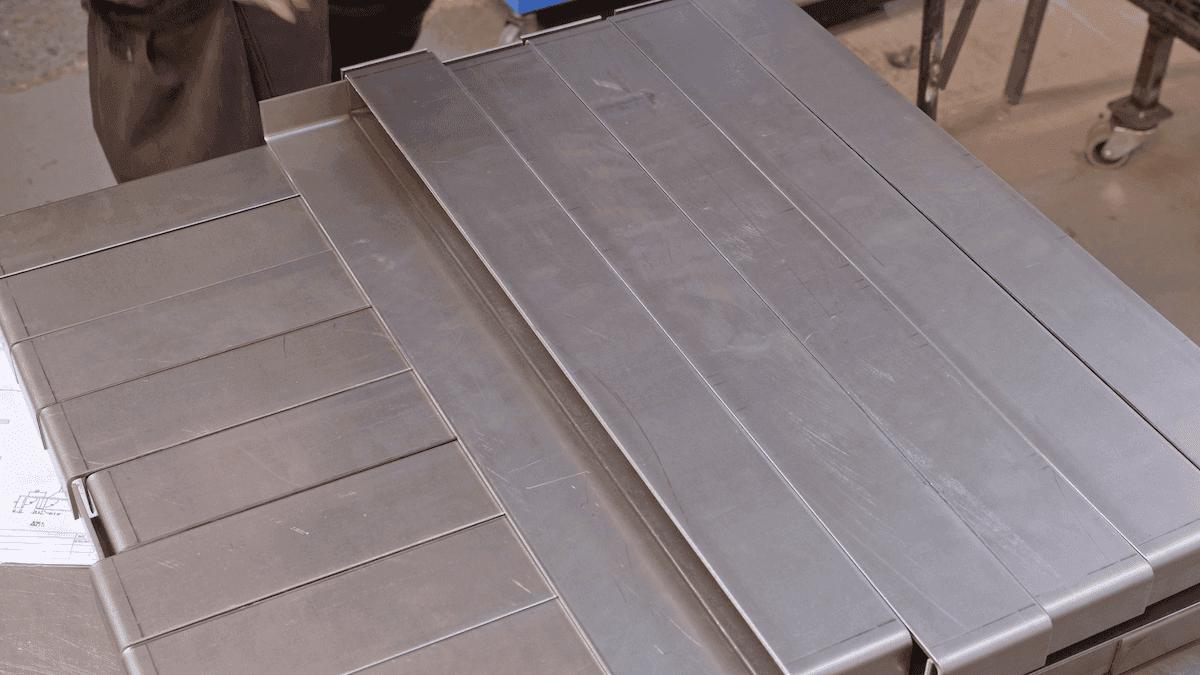

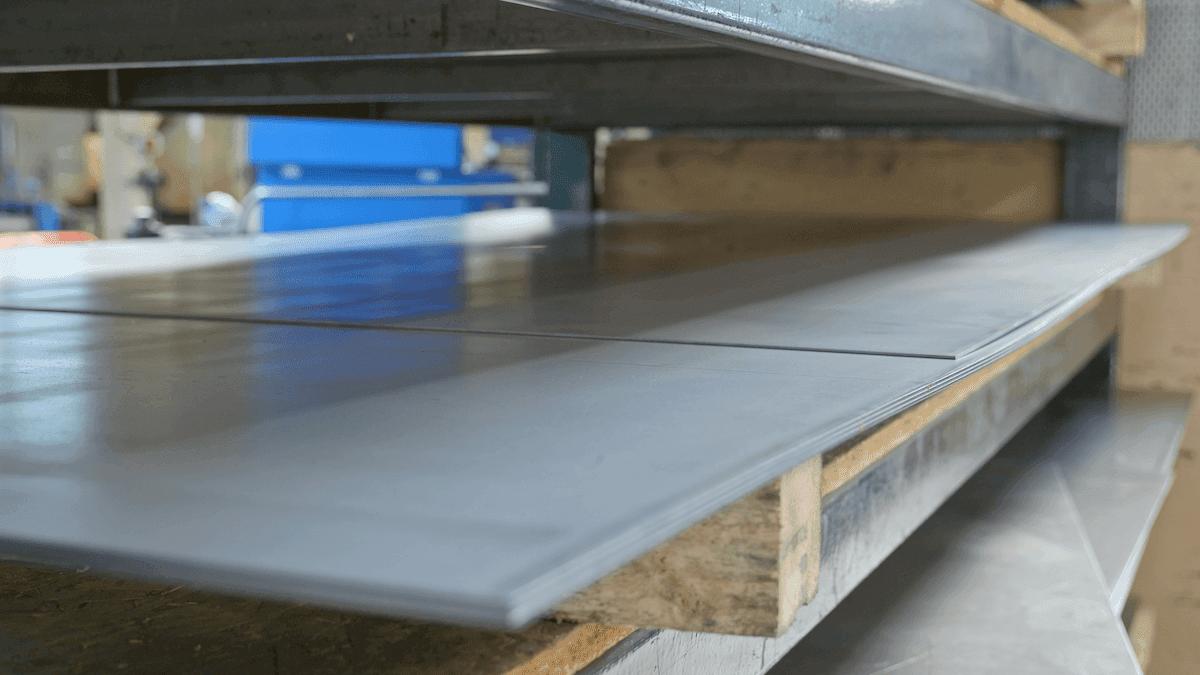

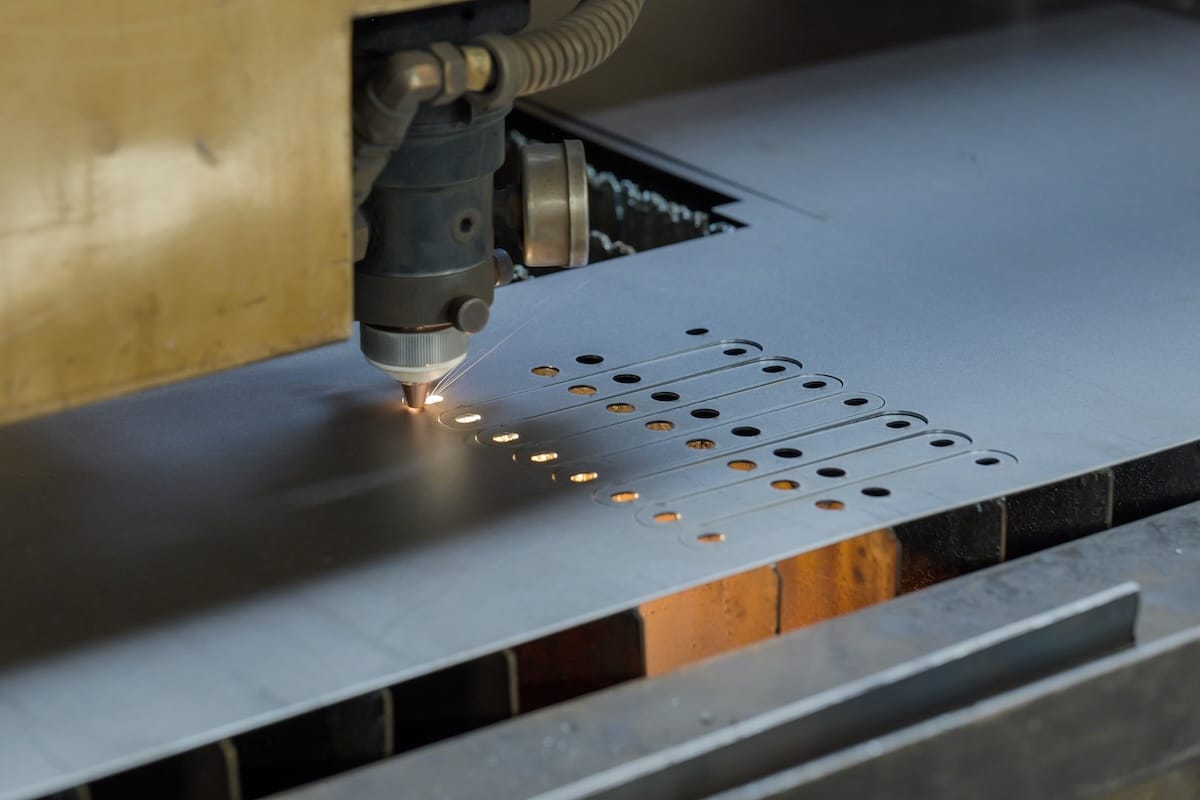

Fabrication of Stainless Steel

Stainless lends itself to fabrication as well as mild steel. It can be cut, formed, welded, and machined from tube, coil, sheet and blanks.

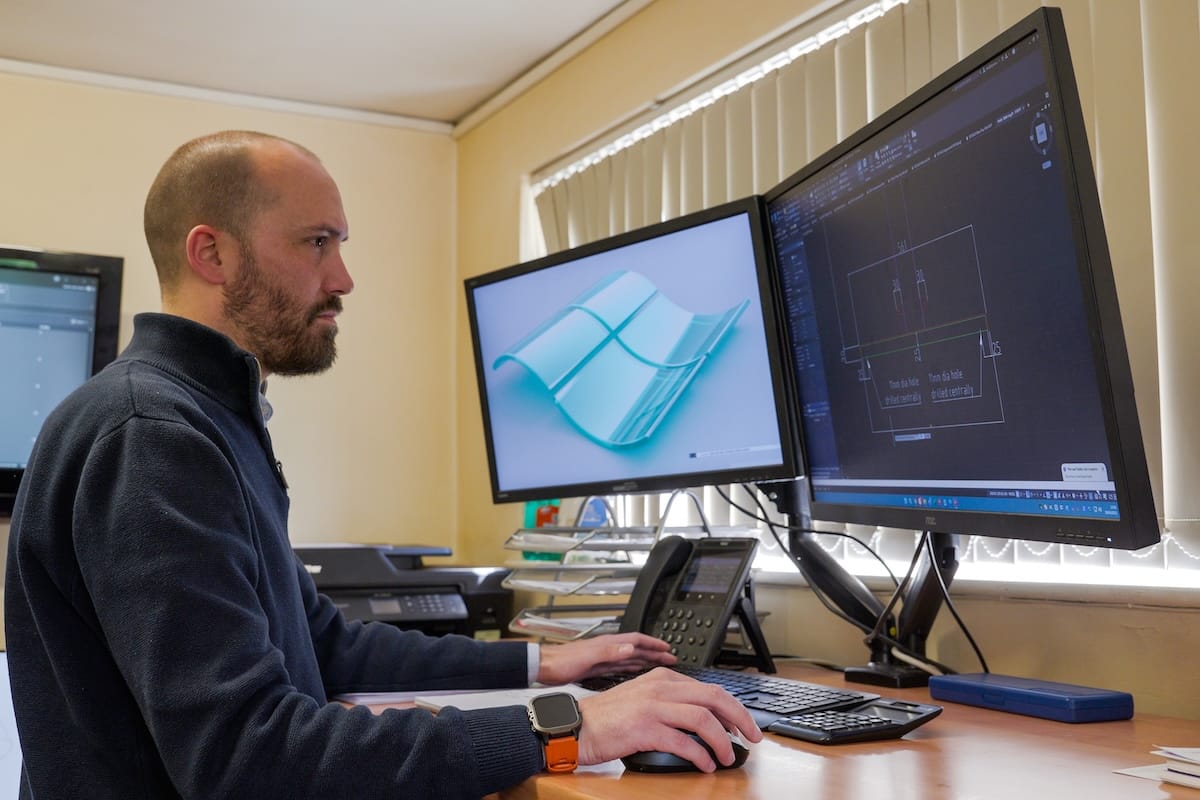

Uses of Stainless Steel

Stainless steel’s resistance to corrosion and staining, its attractive appearance and its lack of maintenance make it ideal for many applications. There are more than 60 grades or specifications of stainless steel and surface finishes which makes it suitable for a wide range of different environments so it’s important to know which grade to use for a particular purpose. As the grade changes, so does the workability of the material. Grade 304 is the most versatile and most widely used stainless specification, available in a wider range of forms and finishes than any other. It is ideal for fabrication and welding, and it is the grade we work with at Dymond.